High-power liquid-cooled EV charging cable

The high-power DC charging cable uses liquid cooling technology to cool down, so that the charging cable maintains a low constant temperature during the charging process, and overcomes the thermal damage to the charging gun, charging cable, and charging pile, thereby increasing the charging current. The principle is to add a liquid cooling circulation system inside the cable, and allow the cooling system and the charging system to coexist through the sealed circulation connection inside the connector. The high-power liquid-cooled DC charging cable can fully charge or quickly charge the battery of an electric vehicle in a short time to increase the cruising range, meet customer needs, improve the utilization rate of electric vehicles, and eliminate users' concerns.

FAFA-E has reached a strategic cooperation with OMG EV CABLE, the world's leading ev cable manufacturer, to provide various standards of electric vehicle charging cables, if you have ev cable needs, please contact us at Sale@fafa-e.com

Advantages of liquid cooling

| high protection | Traditional air-cooled charging piles are generally designed with IP54 design. In dusty construction sites, high temperature, high humidity and high salt fog, seaside and other application scenarios have a high failure rate. Liquid cooling systems can easily achieve IP65 design to meet various harsh scenarios. |

| low noise | The liquid-cooled charging module can achieve zero noise, and the liquid-cooled charging system can adopt a variety of thermal management technologies, such as refrigerant heat exchange and water-cooled air-conditioning heat dissipation, with good heat dissipation effect and low noise. |

| Good heat dissipation | The heat dissipation effect of the liquid-cooled module is much better than that of the traditional air-cooled module. The internal key components are about 10 degrees Celsius lower than the air-cooled module. The lower temperature energy conversion efficiency is higher, and the life of the electronic components is longer. Heat dissipation can improve the power density of the module and apply a higher power charging module. |

| Easy to maintain | The traditional air-cooled charging system needs to regularly clean or replace the filter screen of the pile body, regularly dust the pile fan, remove the dust from the module fan, replace the module fan or clean the dust inside the module. Depending on different application scenarios, annual maintenance is required. 6 to 12 times, the labor cost is high, and the liquid-cooled charging system only needs to regularly detect the coolant and clean the dust on the radiator, which is greatly simplified into operation and maintenance work. |

| Low TCO | At present, there are few applications of liquid-cooled charging system, so the equipment cost is higher than that of traditional air-cooled system. However, from the perspective of equipment life cycle, the whole life-cycle cost of Ling-cooled system is lower than that of air-cooled system. |

| more convenient to charge | Under the same charging power, the outer diameter of the cable using liquid cooling is smaller, and the weight of the cable is reduced by 50%, making it easier and more convenient to use. |

| Charge faster | Using liquid-cooled charging is more efficient. The maximum charging cable of traditional air-cooled charging piles is 200A, while using liquid-cooled charging can provide up to 700A. |

Compared with air cooling, liquid cooling has better performance and higher cost. It will gradually become the mainstream trend of module cooling in the future.

The heat dissipation capacity of the liquid cooling module is 10~20℃ lower than that of the forced air cooling module, and the intelligent noise reduction control can meet the installation and use in noise-sensitive scenarios. The liquid cooling module also has a higher IP level of protection, which is suitable for applications in harsh scenarios such as heavy dust.

The difficulty of liquid cooling heat dissipation mainly lies in the sealing of coolant and cables.

Liquid cooling needs to set up a special circulation channel between the cable and the charging gun, add cooling liquid to the channel, and push the liquid circulation through the power pump to take out the heat to dissipate heat. However, the environment in which the charging pile is installed and used may face extreme weather, harsh environment and other factors. If the pipeline leaks due to poor cable sealing, it is easy to cause the cooling system to fail and cause accidents. Therefore, the liquid-cooled cables used need to pass the tests of high temperature resistance, corrosion resistance, blast resistance, weather resistance and low temperature resistance.

Comparison of heat dissipation performance between air cooling and liquid cooling

| Performance | Air cooling | Liquid cooled |

| Heat dissipation capacity | Restricted, use more charging modules below 30KW | Compared with the forced air cooling module, the temperature is 10~20 degrees Celsius lower, and it is suitable for charging modules above 30KW. |

| Noise control | Greater than or equal to 60 decibels (restricted for applications in residential areas and commercial areas) | less than or equal to 35 decibels |

| Protection class | IP20 | IP54 |

| Service life | 3-5 years | more than 10 years |

| Operation and maintenance | 3-6 times/year | no need |

| Technical Difficulties | Noise, heat dissipation performance | cable seal |

OMG EV Liquid Cooled Cables:

OMG EV Cable entered the electric vehicle charging market in 2009 and entered the high-power liquid-cooled charging business with its own technical reserves. In 2019, the company developed and launched a liquid-cooled charging cable for fast charging of electric vehicles. On the premise that the standard has not been implemented globally, the cable is produced using the IEC62893.4.2 standard. At present, the company's liquid-cooled charging cable business includes water-cooled charging cables and oil-cooled charging cables.

Reference Standard: IEC62893.4.2-2021

Product description:

| Construction | Features |

| 1.Conductor | Rated temperature :-40℃~105℃ |

| Material: Bare Copper | Rated Voltage :DC 1000V |

| 2.Insulation | Maximum current :400A、500A、600A、700A |

| Material: TPE | Maximum power :350KW、400KW、500KW、600KW |

| 3.Filler | cable outer diameter :24mm、28mm、36mm |

| Material: PP Cord | Min : Bending Radius: ≥6*OD |

| 4.Tube | Environmental Requirements:Compliant with RoHS and REACH |

| Material:XLPO OR FEP | The temperature of the job:conductor ≤90℃;surface≤60℃ |

| 5.Sheath | |

| Material: TPU |

What medium does the liquid-cooled charging cable use to dissipate heat?

There are two types of High-power charging cables, oil-cooled and water-cooled, depending on the cooling medium.

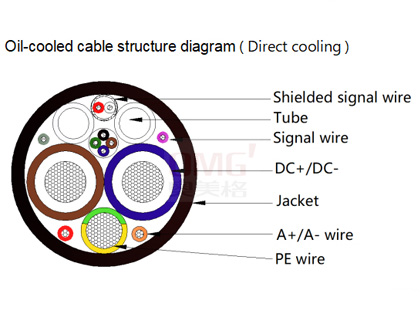

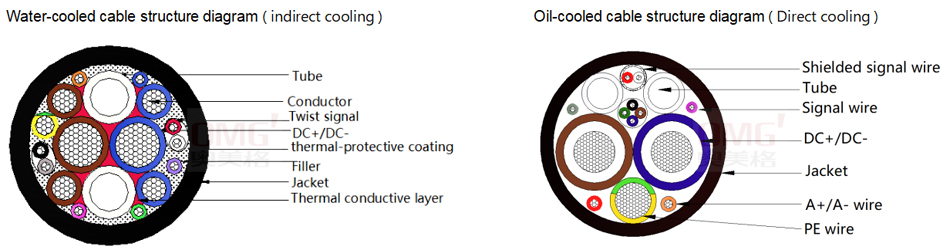

Oil-cooling is to design the insulation layer as an oil tube and directly immerse the conductor part into the oil to increase the current carrying capacity by circulating the insulating oil. The oil-cooled gun is terminated by a specially designed circulation system which not only ensures the circulation of the liquid for cooling, but also does not conduct electricity to keep the insulation safe. This cooling cable is very effective and can reach a high current carrying capacity of 600A.

The other type is water-cooled cable, which means that some water pipes are added inside the cable. The cooling medium is a non-insulating liquid, which can be pure water or antifreeze. The heat generated by the cable is transferred to the liquid through the contact between the insulation and the water pipe, and then the heat is removed by circulation of the liquid, producing a cooling effect and increasing the current-carrying capacity. Since this form of cooling is indirect, the outer diameter of the charging cable can be made smaller. omg ev cable has designed a copper covered water solution that can achieve a high current carrying capacity of 700A.

400KW liquid-cooled charging station application case:

简体中文

简体中文